#Lap splice table code

The code states that bars cannot be separated more than five times the thickness of the concrete. Question: Why don’t we just spread the bars further apart? Answer: That works but does not meet code. The cost per pound will be more, but the cost per foot will be less. They can make deformed #2 bars that generally cost far less than #3 bars because #2 rebar weighs much less. But if you can’t find #2 or it costs as much as #3 and causes more hassle, use #3.Ĭompanies that furnish fence materials usually have #2 Rebar. We are instructing our engineers to utilize #2 Rebar where possible. But fortunately the Monolithic Dome is naturally such a perfect shape for strength that #2 Rebar works in many projects for which we previously used #3. Why is it hard to buy? Extremely little #2 Rebar is used because most concrete requires larger bars on many projects. It needs to be deformed it needs to be grade sixty it needs all these wonderful things, but it is hard to buy.

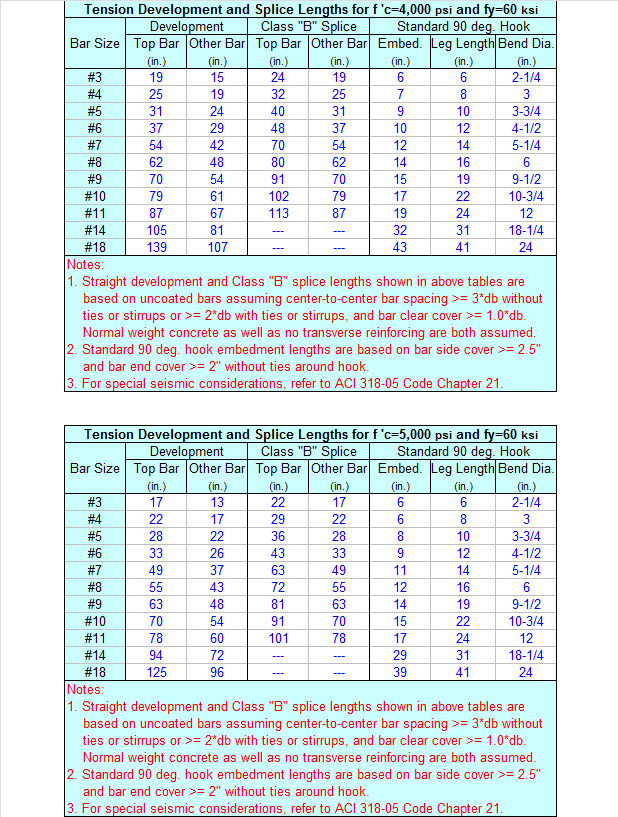

The #2 Rebar is 2/8" or 1/4" in diameter. Rebar comes in various sizes: #2, #3, #4, #5, #6 etc. Rebar SizingĪt Monolithic, we also pay close attention to rebar sizing. We want to keep the laps in the clear so the concrete can wrap around them. So whenever possible, we do not overlap the rebar tightly against itself. If it does not touch, we do an 18" overlap.Ĭonsidering the cost of rebar, these are vast differences. With #4 Rebar, if the bar splice will touch we do a 44" overlap. The engineering world has come up with some numbers to use for bar splices. The two bar diameters provide space for the concrete to go in, around, and between the bars and actually increase the strength. So the recommended way is to bring the bars together and overlap them, but leave at least two bar diameters between the bars. If you touch the two bars together as they overlap, it becomes more difficult for the concrete to go in and around the rebar, and the splice is not considered as strong. When splicing rebar we bring one piece to the other, overlap it a distance, and spray it in place with concrete. So we recommend that you stay away from welding. In fact when I first started, we overlapped and welded the bars together.īut it turns out that unless you’re using A706 rebar – which is very expensive – welding the rebar is not allowed. For years and years, we just overlapped the rebar and tied the bars together. Monolithic’s recommended procedure for splicing rebar has changed.

0 kommentar(er)

0 kommentar(er)